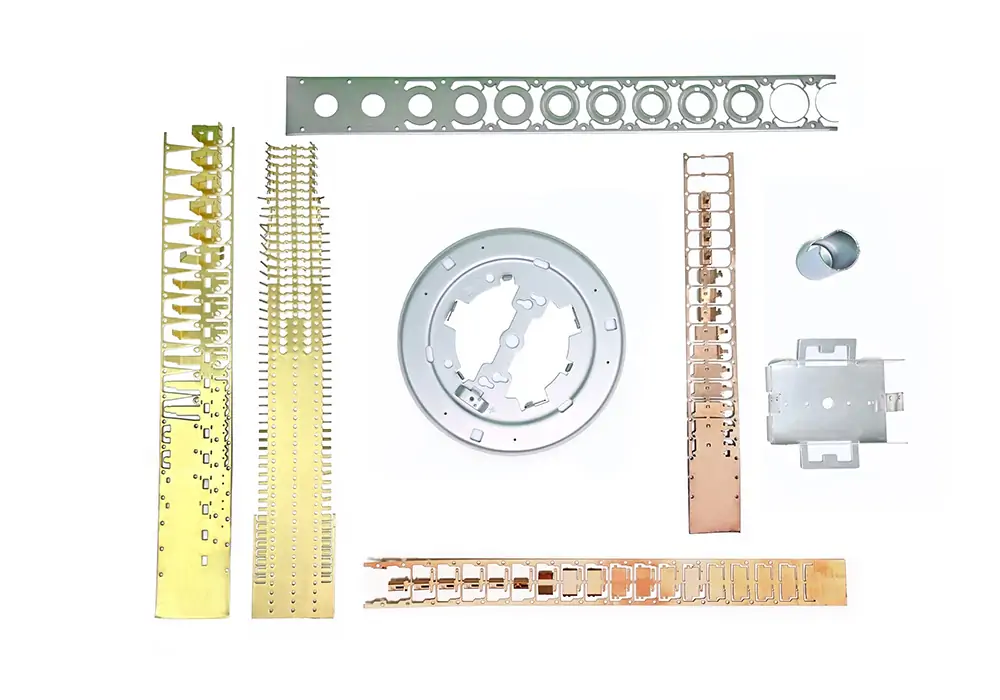

Metal stamping parts are precision-manufactured components that play a critical role in a wide range of applications. Fabricated through the process of metal stamping, forming or deep draw part, these parts offer a combination of strength, durability, and cost-effectiveness, making them indispensable in numerous industries.

We are able to support customers from part design, tooling design (including blanking die, forming die, deep draw die and high speed progressive die) and stamping parts all in house.

Metal stamping parts are widely used in the Power tools industry

The electronics industry also relies heavily on metal stamping parts. Stamped metal brackets, connection pin & socket, housings, and shields provide structural support, protect internal components, and enhance the overall functionality and durability of electronic devices.

A: Our strict quality management system encompasses every stage of the process—from sourcing supplier materials to production, final products, and delivery. Quality is the cornerstone of our operations. We have developed a comprehensive testing system that includes material evaluation, product reliability testing, calibration assessments, and more..