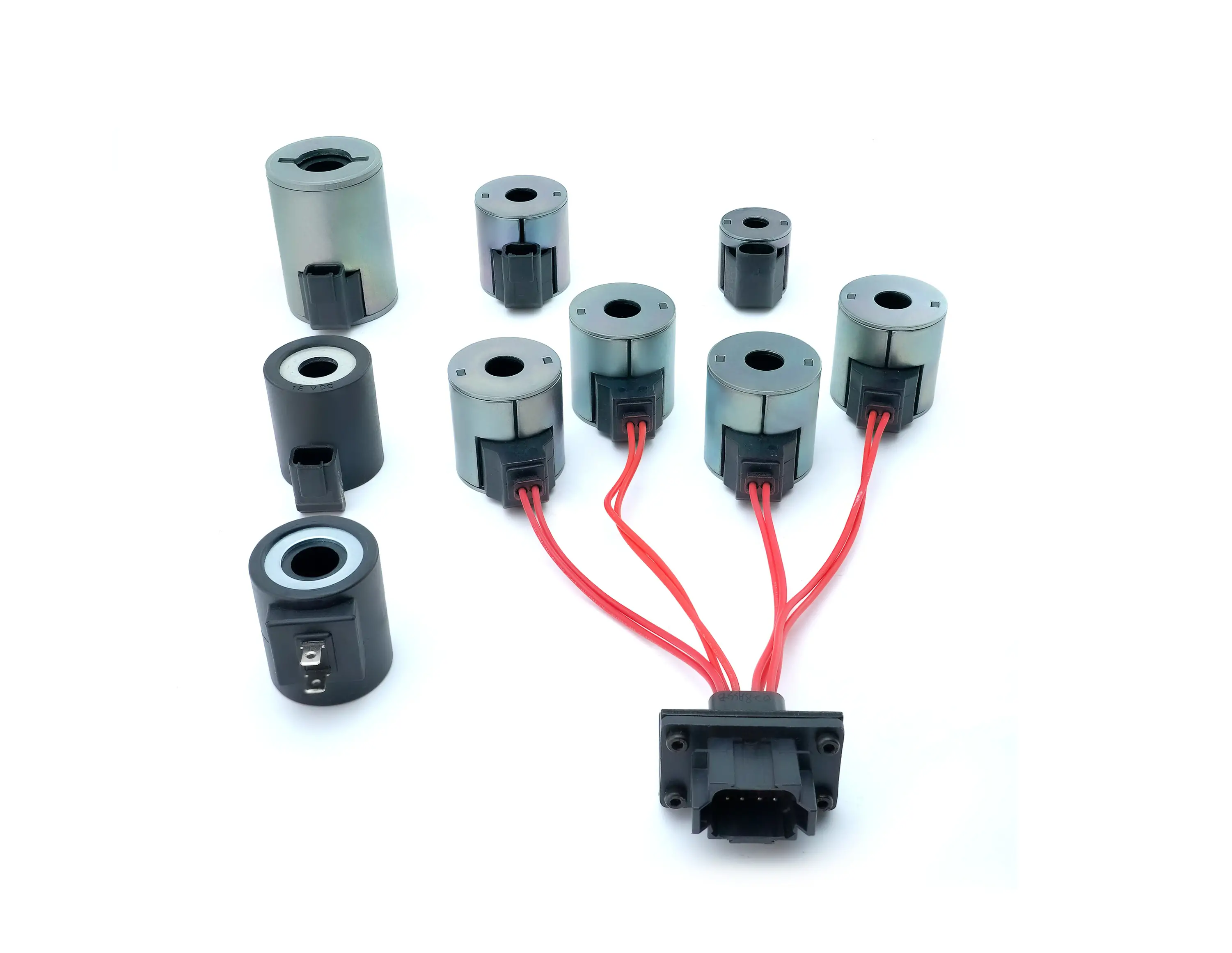

Hydraulic solenoid valve coils, often referred to simply as solenoid coils in hydraulic systems, play an essential role in the operation of hydraulic valves. Solenoid coils function as electromagnets. When energized, they produce a magnetic force that actuates or controls the movement of the valve core within a hydraulic valve. This electromagnetic actuation allows for precise and rapid control of fluid flow in hydraulic systems. Their applications span various industries where precise hydraulic control is critical, ensuring the smooth and efficient operation of machinery and equipment.

0.11mm~0.77mm

200℃ level/ 220℃ level

Standard Voltage: 6VDC,10VDC,12VDC,14VDC,16VDC,20VDC,24VDC,28VDC,36VDC,48VDC

Solenoid Coil size: 08 size coil,10 size coil,12 size coil,1/2" coil, 5/8" coil, 3/4" coil,etc.

Pantene Industrial Co., Ltd has been manufacturing solenoid valve coils for many global renowned solenoid valve brands since 2000. Over the past 24 years, our performance is outstanding in terms of solenoid coils production, quality control, product delivery, and customer service. The total volume of our solenoid coil products has reached up to millions of pieces. We are proud to have been continuously recognised and rewarded with the "SUPPLIER EXCELLENCE RECOGNITION" Platinum Award by our customers (top solenoid valve brand).

we have a professional engineering design team for solenoid coil products, including product engineers, mold design engineers, and process engineers. Our Engineering team closely cooperates with customers to conduct preliminary product analysis( e.g. DFM analysis of product parts and production process analysis), provide effective improvement suggestions, and recommend the most cost-effective and suitable materials.

All molds and dies can be produced in Pantene Industrial. Our workshop is equipped with professional machines including CNC machines, EDM machines, wire cut machines, lathes and grinding machines, CMM testing equipment, and more.

Our metal die, injection mold, and over-molding mold are all designed and made in-house. Metal dies include blanking dies, forming dies, progressive dies, high-speed progressive dies, and deep draw dies.

In addition to tool making, we have an in-house workshop dedicated to stamping the metal washer and metal shell. The bobbin injection and solenoid coil over-molding processes are completed also in-house.

Pantene Industrial has a comprehensive and strict quality control system to ensure solenoid coil quality.

Our QA laboratory enables us to conduct comprehensive verification tests with advanced testing equipments such as salt spray test equipment, X-RAY test equipment, high and low-temperature tester, etc.