During the first phase of collaboration, Pantene Industrial made OEM products for Molded Circuit Board (MCB) of Customer A. The MCB was designed by customer A and PI was responsible for manufacturing.

The original MCB design from Customer A is a one-time encapsulation by over-molding, which causes certain copper traces to be exposed in the air. Exposed copper traces during long-time use may oxidize and rust due to moisture in the air.

To try solve this problem, customer A once sent a PhD level expert over from the United States to try to work out solutions for the oxidation problem, but several coating solutions didn't work.

Upholding our reputation as a reliable OEM partner, the PI engineering team also noticed the customer's concern and proposed a creative and practical suggestion improvement. The solution involves using second-time over-molding to cover the exposed part of the copper traces, thus solving the problem of oxidation and rust.

Following that, we worked more closely with customer A as they highly recognized the technical strength of the PI team. Since then, PI has become the trusted, long-term partner for all molded circuit board projects of Customer A.

1. Professional technical team, proposing creative technical solutions to solve problems of customers.

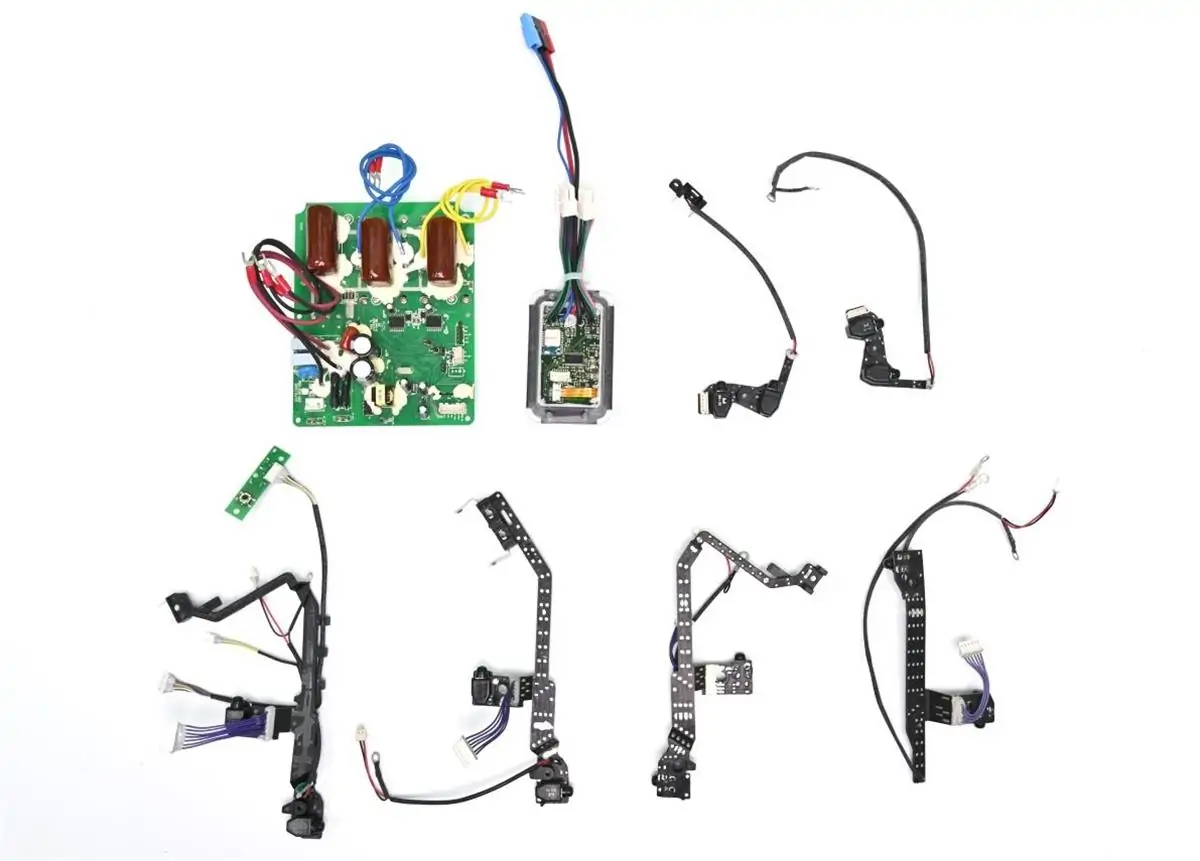

2.One-stop solution capabilities for Molded Circuit Board products, including the design and manufacturing of metal traces dies and over-molding molds, stamping, over-molding, assembly and testing, etc.